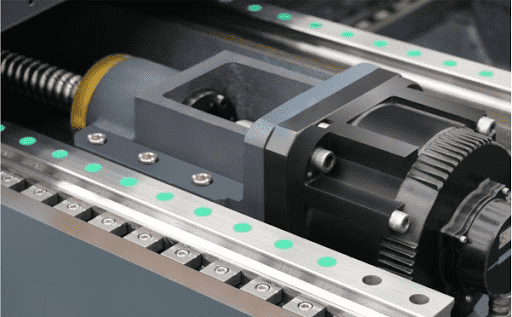

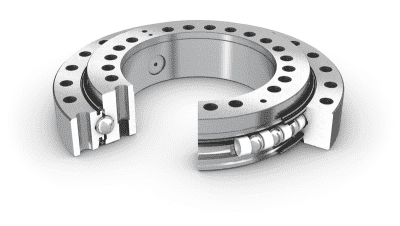

A cikin CNC a tsaye yakin kayan aiki,Keadewayana ɗaya daga cikin abubuwan haɗin haɗin gwiwar waɗanda ke nuna injin gaba ɗaya kuma sun fahimci daidaito na injin. Muna buƙatar shi don yin babban saurin gudu kuma yana tsayayya da aiki mai nauyi a lokaci guda, tare da ingantaccen daidaito da kuma babban anti-mai tsananin ƙarfiTorque ikon, da Keadewa shine mabuɗin kammala teburin tallafi.The shigarwa da kuma prondicle gyara namai zuwasatabiyariHakanan yana da wuya, jeri ya fi wahalar tabbatarwa, duk madaidaicin tebur yana da wahalar inganta.

A sakamakon haka, mafi karbahaye rollersatabiyariana amfani da su ne ke ba da kuɗin farashin kuɗi, mafi kyawun mafita, iyakancewararrun hanyoyin haɓaka, haɓaka daidaito da kwanciyar hankali, kuma mafi girmaɗaukar nauyida ƙarfi. Wannan labarin ya bayyanaaturidon \ dominsatabiyariA CNC Vertical Lathe don cimma cikakken kadarorin injin su.

1.Run-of daidaito

Kwace bmasu kunne gudu-wajeza a iya raba su cikin sauri-waje da asynchronous Run-fita, a cikin wane irin gudu-waje a kan teburin tebur.satabiyari asynchronous gudu-waje, karami na karsheradial da gudu gudu-wajena aiki da kuma mafi girman daidaito. A cikin zabi nasatabiyari alama da matakin daidai, ba da shawarar ba kawai mai da hankali kan sataHoto-waje, amma ya kamata ya sami zurfin fahimta game da tasirin tasirinsatabiyariMatsakaicin Matsayi na ASYchronous

2.Rape da haƙuri

Da Keadewamashi hawa samandazobear sittinna bukatar lebur, perpendicularity, zagaye da silinda wanda suke daidai dadaidaicisatabiyari. Gudanar da wadannan fom da haƙuri da wuri ba wai kawai yana samar da ingantacciyar Majalisar Dealmachy ba, amma kuma yana hana mayar da hankali da damuwa sakamakon yawadazobeInterner da waje zobekuma tsawantawarayuwar sabis nasatabiyari. Dangane da ka'idodin aiki na tsari da zobeMatsayi mai haƙuri, ana bada shawara don ƙarfafa mu kai tsaye don dacewa da su sataBiyan daidaito.

3. Axial prodecload

Gwajin yankan CNC na yankewa na CNC yana biyan hankali sosai game da girman fuskanta da da'irar waje, kuma ɗaya daga cikin maɓallan tsarin. Rigorty na tsarin ya hada da tsayayyen tsarin tsarin, da tsayayyen na satabiyari, da sauransu tsayayyen na satabiyarisau da yawa ya dogara daKeadewaAxial pradload.

Saboda haka, yana da matukar muhimmanci a yi la'akari da tasirin zafin jiki da kaya, kuma saitaAxial prodpload nasatabiyari.

Lokaci: Aug-31-2020