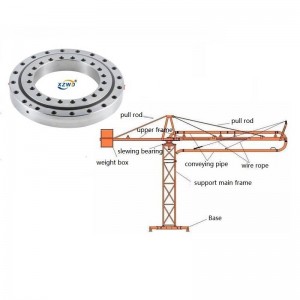

masu nauyi mai nauyi mai nauyi tare da zoben yankan kaya na waje

An ƙididdige lamba da ƙarfin lanƙwasawa na gears a ƙarƙashin ƙayyadaddun nauyin nauyi da gajiyawa kuma an ƙididdige su bisa ga ISO6336-1: 2006, ISO6336-2: 2006 da ISO6336-3: 2006 bi da bi.Sf shine 1.48 kuma an daidaita share ragamar gear don mafi girman matakin radial daga cikinkashe kaigear farar da'irar.Matsakaicin sharewar haƙori yawanci 0.03 zuwa 0.04x modules, kuma ɓangarorin gear mesh na gears ɗin pinion gears akan duk kewaye yana buƙatar sake duba bayan an gama ɗaure na ƙarshe.kashe kai.

Single-jere hudu lamba ball ball slewing na ciki ball machining daidaito da kuma na ciki raceway machining daidaito ba high, ko akwai ingancin lahani da kuma rashin lubricating mai a cikin raceway abin nadi da spacer karo, kai tsaye rinjayar da santsi aiki na kashe zobe. da hayaniya, don haka lokacin duba lahani na zobe, wani lokaci ta hanyar maye gurbin ƙwallon don rage yawan gazawar.

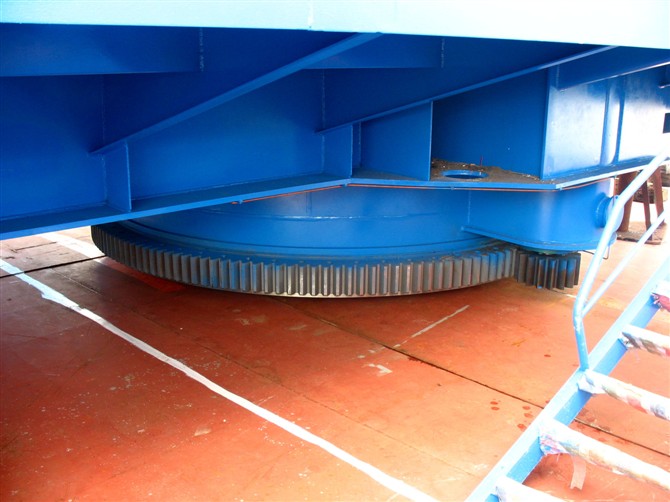

Saboda kayan da ke ƙarƙashin lodi bayan dogon aiki, za a sami ƙaramin ƙarfe ko ɗigon ƙarfe kusa da layin farar, rami ko tsinke guntun ƙarfe, samuwar rami ko hakora.The slewing hali hakori surface pitting tare da karuwa a cikin aiki lokaci da kuma fadada sabõda haka, da slewing qazanta raga hakori lalacewa, hasumiya crane rotary amo da kuma tasiri ƙara, da sake zagayowar na tasiri saukar da karfe barbashi da kuma hanzarta lalacewa na slewing zobe hakori surface. samar da muguwar zagayowar.Bugu da ƙari, masana'anta da haɗuwa da motar mai farawa a cikin injin ƙirar ƙira yana da nasa lahani don samar da tasirin jitter, kuma tsarin haɗin gwiwar motar motar tare da ɗaukar kisa ba shi da kwanciyar hankali, wanda kuma yana ƙara yawan jitter da amo mai reverberation. decibels.

Idan ingancin walda bai kai daidai ba, lalacewar walda yana buƙatar sake yin aiki da sake welded.A cikin gyaran walƙiya gyaran gyare-gyare ba kawai zai haifar da sabon damuwa na walda ba kuma flatness na injin da aka yi amfani da shi zai yi tasiri mai yawa, a lokaci guda waldawar halin yanzu da aka haifar a cikin slewing bearing ta cikin ciki na mirgina jiki da slewing zobe Raceway zai kuma yi tasiri. haifar da wani lalacewa.Bugu da kari, kurakurai na taro a cikin taron masana'antu, shigar filin filaye da zaren abin rufe fuska kuma na iya haifar da hayaniya ko magana mara kyau idan buƙatun ba su cika ba.

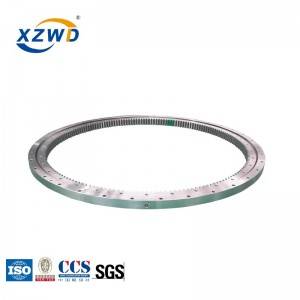

slewing zobe main siffofin ne na waje da kuma na ciki irin, da manya da kanana gears raga talauci, wani lokacin m, wani lokacin sako-sako da, a cikin slewing zobe hakori gudu fitar matsakaicin matsayi meshing ma m samar amo.Don haka tsarin masana'anta yana da mahimmanci.Slewing bearing kawai barin masana'anta a cikin rashin aiki zai ba da sautin ƙarfe na ƙarfe mai jujjuya uniform, wanda yake al'ada.Kamar a cikin yunifom ringin na yau da kullun tare da wani babban ƙarar wanda ba daidai ba ne.Akwai dalilai da yawa na gazawar.

1. Our masana'antu misali ne bisa ga inji misali JB / T2300-2011, mu kuma an samu m Quality Management Systems (QMS) na ISO 9001: 2015 da GB / T19001-2008.

2. Mun sadaukar da kanmu ga R & D na musamman slewing hali tare da high daidaici, musamman manufa da bukatun.

3. Tare da wadataccen kayan aiki da haɓakar haɓaka, kamfanin zai iya samar da samfurori ga abokan ciniki da sauri da sauri kuma ya rage lokaci don abokan ciniki su jira samfurori.

4. Ƙwararrun ingancin mu na ciki ya haɗa da dubawa na farko, nazarin juna, in-processing control da kuma samfurin dubawa don tabbatar da ingancin samfurin.Kamfanin yana da cikakkun kayan gwaji da kuma hanyar gwaji na ci gaba.

5. Ƙarfafa ƙungiyar sabis na tallace-tallace, lokaci-lokaci magance matsalolin abokin ciniki, don samar da abokan ciniki tare da ayyuka daban-daban.